| |

|

Mini-Sextant Tracking Mount |

| |

| |

|

|

| |

| |

|

|

|

| |

|

Photo-Sonics is pleased to announce the addition of the

Mini-Sextant to our line of optical tracking mounts, joining

our proven Nano-Sextant, Mobile Multi-Spectral TSPI Systems

(MMTS), Cine-Sextant and Super-RADOT systems.

The design of the Mini-Sextant provides four sensor

stations for collection of highly accurate

Time-Space-Position-Information (TSPI) or Engineering

Sequential Data (ESD) from high dynamic airborne targets.

The Mini-Sextant has a significant amount of torque in

azimuth and elevation and will provide dynamic performance

equal to that of the MMTS.

Its unique balance of available torque, positioning

accuracies and payload flexibility allows the system to be

configured with optics best suited for close-in launch

missions or down range for longer range fly-out missions

without compromising dynamic performance or accuracy.

Payload Flexibility - Photo-Sonics has

over

50 years experience in the design selection,

fabrication and integration of sensor suites

|

|

Mini-Sextant |

on Optical

Tracking Systems (OTS). Depending

upon your mission needs, a fully integrated Mini-Sextant can be

configured with a combination of long-range / short-range optics with a combination of long-range / short-range

optics, and laser range finders. While the recommended maximum total payload is 400 pounds, additional payload

may be supported with reduced dynamics and accuracies.

|

|

|

| |

| |

| |

| |

|

|

| Mini-Sextant: Palette Mounted |

Mini-Sextant: Pedestal Mounted |

| |

|

|

|

| |

Robust Pedestal Construction —

Photo-Sonics utilizes Almag‑35, an aluminum magnesium

alloy,

which provides excellent corrosion resistance to

support long life with minimal maintenance in the

harshest

environments. We

use only full size bearings to provide the highest stability

and accuracies,

as opposed to narrow diameter bearings

found in lesser systems.

Powerful, DC torque motors are

provided in both

the azimuth and elevation axis are coupled to the identical

9-inch diameter, 24-bit

optical encoders used in our

flagship tracking system, the MMTS.

Pedestal Support

Electronics —

The modularity of the Mini-Sextant control electronics

supports

several installation scenarios.

The Trunnion Computer Unit, vital for real-time

operations of the

pedestal, sensors and optics is located

within the pedestal.

The Digital Servo Amplifier (DSA),

RFI power filters

and I/O panel are packaged in enclosures at the pedestal

site. The

remaining

electronics such as Base Computer Unit (BCU),

Video Switches, Video Trackers, Video Recorders,

etc., are

installed in the Operator's Console which can be located

in a mobile Operations Van or at

the user’s Mission

Operation Center. |

|

|

| |

|

|

|

| |

|

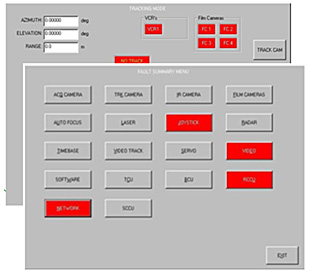

Control Software — The ARGUS control

software

provides all the functionality the user

would expect of

an advanced TSPI tracking system. It provides a

single interface for the tracking pedestal,

sensors,

auto-tracking, radar, calibration, target simulation

and

diagnostics of the complete tracking system.

Control of

the

system is simplified via an intuitive touch screen

GUI. The standard ARGUS application can control up to

10

sensor stations, in addition to radar and lasers,

allowing

a

single-operator complete control of all

aspects of a complex

and highly capable system from

a remote location. It also

provides the control of single

and dual-gate auto trackers

and fixed focal length and

zoom lenses and focus tables.

Automated Star

Calibration are incorporated to yield the

highest TSPI

accuracy of any optical tracking system

manufactured today. Visit the ARGUS software page. |

|

|

| |

|

|

|

| |

|

Operator Console -

Photo-Sonics offers a

variety of console configurations, from our

full- size

console (for location in mission

control center) to

smaller, compact consoles

suitable for mobile command

vehicles or multiple packing cases for transportability.

The default connection between the pedestal and the remote

console is via a single-strand,

single-mode 'dark' fiber

optic cable, which

allows for up to 20 km separation.

Alternative

interfaces including shared fiber optics and

microwave are also supported.

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

A standard console consists

of the

following items:

· 19" Touch-Screen Monitor

for the main GUI

interface

· Video Monitors

(2, 3, or 4

screens available)

· Operator Control Panel

· Mini Keyboard with Control

Stick and Operator

Controls

· Console Computer

· I/O Panel (Fiber optics,

Ethernet switches)

· Optional UPS

System

Options:

Trailer Configuration

The Mini‑Sextant can be

configured

with a ruggedized

trailer system customized for

operations at multiple sites.

Shipboard Stabilization

Photo-Sonics can configure

the Mini-Sextant with a

stabilization system to allow

use of the system at sea.

|

|

Mini-Sextant System Specifications

|

|

System Accuracy, Fixed Mount |

±10 arc-seconds (50 micro-radians), 2σ

|

|

Bearings

|

28” diameter azimuth thrust

bearing

16” diameter elevation ball

bearing

|

|

Drive System

|

Direct drive DC torque motors (brush type)

|

|

Torque

|

Azimuth

:

350 foot pounds (475

N•m)Elevation

:

350 foot pounds (475

N•m)

|

|

Velocity (nominal payload)

|

Azimuth

:

120°/second

Elevation

:

120°/second

|

|

Acceleration

(nominal payload)

|

Azimuth

:

120° sec²

Elevation

:

120°

sec²

|

|

Closed Loop Servo Bandwidth

|

Azimuth

:

8-10 Hertz

Elevation

:

8-10 Hertz

|

|

Nominal Payload

|

200 pounds per platform

(at rated payload moment of inertia design

specification)

|

|

Non-Orthogonality

|

± 5 arc seconds

|

|

Encoders (optical, absolute)

|

24-bit

|

|

Elevation Travel

|

-15° to +195°

|

|

Azimuth Travel

|

±270°

(cable wrap configuration)

Continuous

(slip-ring configuration)

|

|

Transit Locks

|

Locking stow pins in AZ and EL axis

|

|

Height

|

78”

(pedestal base)

|

|

Power

|

3-phase European or US AC power

|

|

|

|

| |

|

|

|

|

|

|

| |

<back to top> |

|

| |

|

|

|

© 2019 Photo-Sonics, Inc. |

| |