The original RADOT Tracking Systems were developed by Photo-Sonics, Inc. for the United States Army Kwajalein Missile Range (USAKMR) approximately 10 to 15 years ago. The RADOTs in use are capable of collecting TSI component data to a very high degree of accuracy using a multiple-station solution technique.

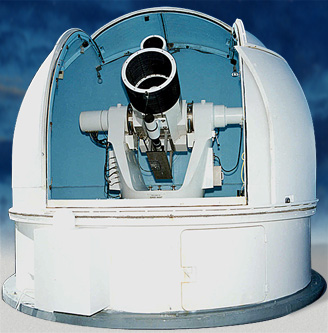

The basic design requirement for the Super Radot includes a base assembly

which contains the azimuth drive motor, tape cables, and the azimuth

carriage assembly. The elevation axis is comprised of the

elevation drive motors and the payload carrying platforms. A

separate control console is located adjacent to the mount. The

Super Radot provides smooth, vibration-free tracking within the range of

540 in azimuth and -10 to +95 in elevation. The

pedestal is enclosed in an Astrodome shelter. Electrical

and electronic facilities required to operate the mount are incorporated

into a local console within the Astrodome and a remote console located

in a control room which also houses a computer and Tracking Error

Detector System (TEDS) that automatically maintains target tracking once

a target is acquired. In addition to TEDS, the system also

operates in manual tracking mode, controlled by a stick controller

located in the control room and also in computer mode, which uses

pedestal position data and external target data to produce a tracking

error signal.

The basic design requirement for the Super Radot includes a base assembly

which contains the azimuth drive motor, tape cables, and the azimuth

carriage assembly. The elevation axis is comprised of the

elevation drive motors and the payload carrying platforms. A

separate control console is located adjacent to the mount. The

Super Radot provides smooth, vibration-free tracking within the range of

540 in azimuth and -10 to +95 in elevation. The

pedestal is enclosed in an Astrodome shelter. Electrical

and electronic facilities required to operate the mount are incorporated

into a local console within the Astrodome and a remote console located

in a control room which also houses a computer and Tracking Error

Detector System (TEDS) that automatically maintains target tracking once

a target is acquired. In addition to TEDS, the system also

operates in manual tracking mode, controlled by a stick controller

located in the control room and also in computer mode, which uses

pedestal position data and external target data to produce a tracking

error signal.

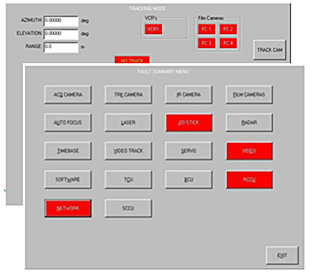

Control Software - The ARGUS control software

provides all the functionality the user would expect of

an advanced TSPI tracking system. It provides a

single interface for the tracking pedestal, sensors,

auto-tracking, radar, calibration, target simulation and

diagnostics of the complete tracking system. Control of

the system is simplified via an intuitive touch screen

GUI. The standard ARGUS application can control up to

10 sensor stations, in addition to radar and lasers,

allowing a single-operator complete control of all

aspects of a complex and highly capable system from

a remote location. It also provides the control of single

and dual-gate auto trackers and fixed focal length and

zoom lenses and focus tables. Automated Star

Calibration are incorporated to yield the highest TSPI

accuracy of any optical tracking system manufactured today.

Visit the ARGUS software page.

| Nominal Payload | 600 pounds |

| Maximum Payload | 1000+ pounds with reduced accuracy and performance |

| Standard Configuration | On-Axis optical payload with no man-on-the-mount |

| Optional Configuration | On Axis Optics with Off Axis Radar |

| Azimuth Torque | 1500 foot pounds |

| Elevation Torque | 2 x 300 foot pounds |

| Azimuth Acceleration | 100+ degrees/second2 with nominal payload |

| Elevation Acceleration | 100+ degrees/second2 with nominal payload |

| Azimuth Velocity | 100+ degrees/second |

| Elevation Velocity | 100+ degrees/second |

| Weight | 6500 lb trailer mounted pedestal with single axle |

| Dimensions | 125"L (plus 33" trailer tongue) x 87.25"W x 93.71"H |

| Calibration | No Radar: Turn & Dump, Star Calibration |

| Radar on Top | Star Calibration only |

| Radar On Side | Turn & Dump, Star Calibration |

| Encoder | 24 bit absolute position optical encoder with 23 bit quadrature output for velocity |

Photo-Sonics, Inc.

818-842-2141 (ph - switchboard paging)

818-842-2610 (fax)

mail@photosonics.com