The Photo-Sonics Compact Tracking Mount (CTM) provides a high performance TSPI, vibration-free data gathering system in a rugged, portable configuration. A primary goal was to design a system that could be transported, set up and operated by one individual, while retaining features of the typically larger tracking mounts. With over 30 years of experience in designing and manufacturing tracking systems, Photo-Sonics has incorporated the same high performance and quality engineering found in the field-proven Cine-Sextant Tracking Mount.

The Photo-Sonics Compact Tracking Mount (CTM) provides a high performance TSPI, vibration-free data gathering system in a rugged, portable configuration. A primary goal was to design a system that could be transported, set up and operated by one individual, while retaining features of the typically larger tracking mounts. With over 30 years of experience in designing and manufacturing tracking systems, Photo-Sonics has incorporated the same high performance and quality engineering found in the field-proven Cine-Sextant Tracking Mount.

The CTM utilizes three custom, direct-drive torque motors which provide 1500 foot-pounds of torque in the azimuth axis and 750 foot-pounds of torque in the elevation axis. This high level of torque is provided to maintain maximum dynamic tracking accuracy when the CTM is moved in close to the target and when high acceleration is required. It is also essential for maintaining consistent tracking performance with heavy or unbalanced payloads.

All major structural members including the base casting, azimuth carriage, and instrumentation platforms are cast of high strength aluminum alloy. The overall dimensions and weight of the CTM allow for air transportation in a C-130 and attachment hardware on the trailer is provided for lifting the system by crane or helicopter. Four motorized jacks, located at the extreme corners of the trailer, provide a wide footprint for a stable tracking base. The CTM is offered in both man-in-the-mount configuration and/or an unmanned remote control console configuration.

Applications

Missile Launch / Ordnance Separation / Target Interception / Test Track / Take-Off and Landing

Features

Mobile / High Degree of Accuracy / High Dynamics / Versatile Payload / Sidereal Rate Tracking / Star Calibration /

Manned or Unmanned Operation / Remote Control Capability / Target Simulation / Diagnostic Software / Motorized

or Manual Leveling Jacks / Top and Bottom Instrumentation Mounting Platforms (4) / Camera Boresighting, Alignment,

and Loading from a Standing Position on the Ground / Adjustable Platform Height Provides for Balancing Equipment

Load / Unique Direct AZ-EL Torque Motor Design / Optical Encoders Up to 23 Bit / Parallax and Elevation Adjustments

/ Built-in, Selectable, Dual-Power Sighting Scope (8, 15, or 24X) with Lighted Reticle / Dynamic Braking / Open Sight

Acquisition Aid with Lighted Reticle

Sensors

Digital and Film Cameras / IR Cameras / Tracking Video / Acquisition Video / Radar: Tracking - Range /

Laser: Ranging

Available Imaging and Related Equipment

● Photo-Sonics 35mm-4EL High-Speed Film Camera with Data Head and Digital Phase Lock Servo Control

● Photo-Sonics Auto-Focus Tables

● Photo-Sonics 100-inch and 48-inch Lenses

● Photo-Sonics Barlows for conversion of 100-inch lens to 120, 150, 180 and 200 inch

● Monochrome CCD camera, ruggedized, with 7" zoom lens (400-3000mm) for target tracking and stellar calibration

● Color CCD camera and 3.25" zoom lens (50mm~700mm) for remote target acquisition

● Photo-Sonics DV1 High-Speed Digital Camera

● Infrared Imaging System

● Weibel Doppler Tracking Radar

● Laser Range Finder

● Long-record digital cameras

● Zoom lenses

● RC telescopes

● Metric zooms

● Auto-tracker with Dual-Gate option

Control Electronics

Control Electronics

● Dual Gate Video Tracker

● Global Positioning System (or IRIG-B) for timing and position

● Photo-Sonics Film Data Recording System

● Video Data Recording System

● Optical Encoders up to 23 bit

● On-Board Computer systems (3): 15 slot VME in trailer, 5 slot VME in trunion and 19-inch

rack-mounted PC in the Remote Control Console

● Dual Bay Remote Control Console

Argus Software Components

Argus Software Components

● Comprehensive pre-flight preparation and calibration. Includes built-in tests.

● Real time TSPI input and output

● Nominal Trajectories

● Target Simulation

● Celestial Calibration designed specifically for an off-axis tracking system with sensors mounted

on either side of the rotational axis for better than 5 arc-second accuracies

● Remote control capabilities from the Remote Control Console

● Extensive Fault Detection

● Comprehensive Man-Machine Interface

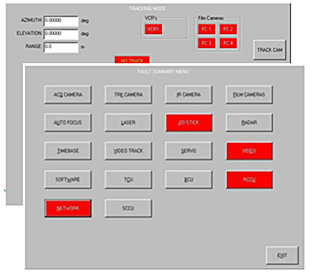

Control Software — The ARGUS control software provides all the functionality the user would expect of an advanced TSPI tracking system. It provides a single interface for the tracking pedestal, sensors, auto-tracking, radar, calibration, target simulation and diagnostics of the complete tracking system. Control of the system is simplified via an intuitive touch screen GUI. The standard ARGUS application can control up to 10 sensor stations, in addition to radar and lasers, allowing a single-operator complete control of all aspects of a complex and highly capable system from a remote location. It also provides the control of single and dual-gate auto trackers and fixed focal length and zoom lenses and focus tables. Automated Star Calibration are incorporated to yield the highest TSPI accuracy of any optical tracking system manufactured today.

| Size | 92"L x 82"W x 85.6"H (plus 18" trailer tongue) |

| Weight |

Mount - 6,240 lbs. (no payload) Tongue Weight - 1,260 lbs. |

| Payload | 600 lbs. total with man in the mount; 900 lbs w/o man |

| Travel |

Azimuth - 600° total Elevation - 100° total |

| Torque |

Azimuth - 1x1500 ft. lbs. permanent magnet motor Elevation - 2x375 ft. lbs. permanent magnet motors |

|

Acceleration (with 600- pound payload) |

Azimuth - >2.5 radians per second per second Elevation - >3.5 radians per second per second |

| Velocity |

Azimuth and Elevation - configurations available from sidereal to 1.75 radian per second |

| Dynamic Range | 1000:1 |

|

Bandwidth (with 600-pound payload) |

Azimuth - 12 Hz Elevation - 15 Hz |

| Non-orthogonality | <15 arc seconds |

| Bearing Wobble | < 6 arc seconds |

| Power Requirements |

208VAC, 60 Hz, 3 phase Total peak power 7.5 KVA providing 1500 ft. lbs. azimuth torque and 750 ft. pounds elevation torque |

| Road Clearance | 12 Inches |

| Roadability |

Highway

- 55 mph Unimproved Roads - 35 mph |