Since the founding of Photo-Sonics, Inc. some seven decades ago, the company's record of performance and integrity is a recognized achievement in the photo-optical instrumentation field and the motion picture industry. The contribution by Photo-Sonics, Inc., to this discipline has been continuously demonstrated by the high performance level exhibited by equipment now in use at the nation's major missile test ranges, defense installations, scientific laboratories, military test ranges, military research centers, in military aircraft, and at major corporations.

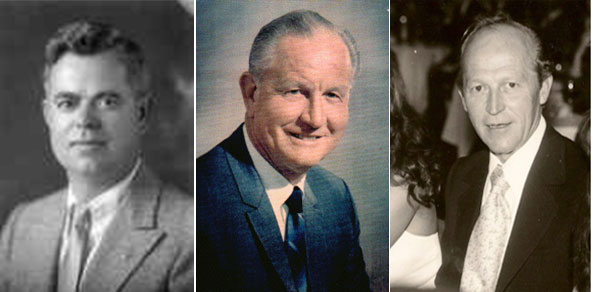

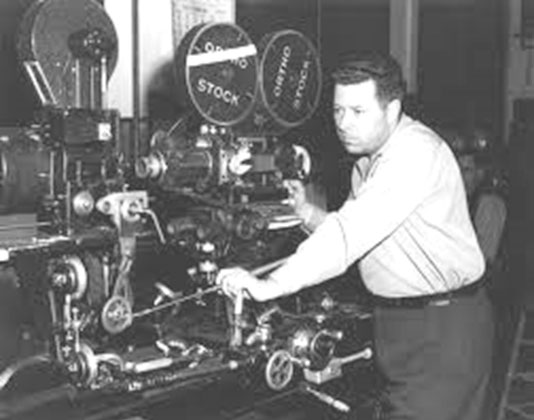

In the late 1920's Adolph Furer founded the business as Acme Tool and Manufacturing Company. The company began primarily as a contract machine shop. In ensuing years the company moved into the motion picture field through contact with Walt and Roy Disney. The Disney's were in a specialized and entirely new field of photography for which appropriate equipment, including animation cameras, was not available. The initial business development was to manufacture specialized equipment for animation photography and develop new or modified cameras for this specialized application.

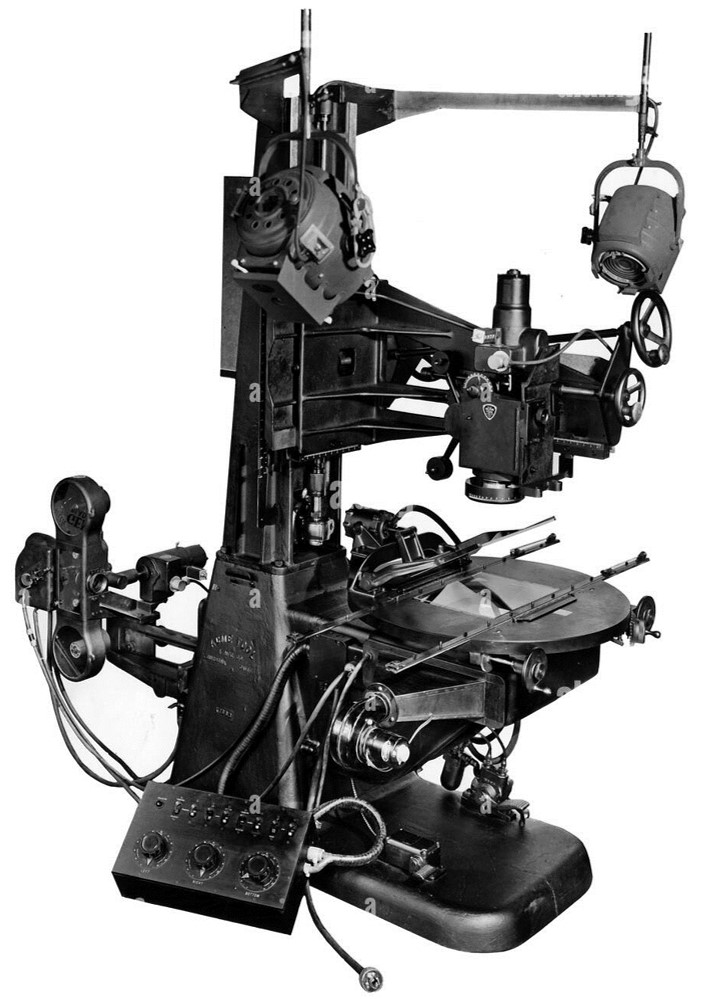

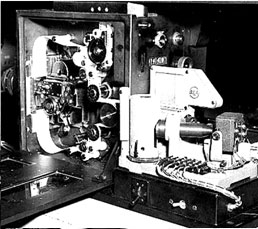

In 1939 Adolph Furer sold his interest to his son, Edward, who oriented the business toward the development and manufacture of special effects motion picture equipment. In 1949 the company name was changed to Producers Service Company. At that time the company had achieved Mr. Furer's primary objectives as a company that manufactured self-developed, proprietary products. The company's primary products were animation stands, optical printers, matte printers, process cameras, and related accessory and peripheral equipment.

In the late 1940's and early 1950's, because of the U.S. Government's emphasis on missiles as new weapons development, a requirement developed for high speed instrumentation cameras. Since the company had a history of building precision cameras, it was a natural progression to enter into this new field.

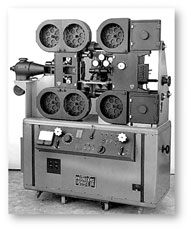

In 1952 Photo-Sonics, Inc. was formed to design, manufacture and distribute photo-optical instrumentation. About 1960 the companies were reorganized to better concentrate efforts toward photographic instrumentation equipment. Acme Camera Corporation, which manufactured special effects motion picture equipment, was transferred to Photo-Sonics, Inc. Producers Service Company whose sole activity then was the leasing of Acme equipment was sold. Producers Sales Corporation, which engaged in the distribution and sale of Acme equipment, was liquidated. Photo-Sonics, Inc., the sole remaining organization, continued to develop and manufacture high speed instrumentation cameras and associated systems.

Walt and Roy Disney contract with the company to modify a Bell & Howell motion picture camera to provide stop motion capability for the production of animation.

Walt and Roy Disney contract with the company to modify a Bell & Howell motion picture camera to provide stop motion capability for the production of animation.

Photo-Sonics formed to design and manufacture photo-optical instrumentation.

Photo-Sonics formed to design and manufacture photo-optical instrumentation.

Company wins major contracts from IBM and Goodyear for special film movements used in the bomb guidance and navigation system of the B-52 bomber.

Company wins major contracts from IBM and Goodyear for special film movements used in the bomb guidance and navigation system of the B-52 bomber.

Company designs 70mm-10A high-speed pin-registered camera (80 pictures per second).

Company designs 70mm-10A high-speed pin-registered camera (80 pictures per second).

Company designs 16mm-1B high-speed rotary prism camera for use at Hurricane Mesa Test Track in Utah (1000 pictures per second).

Company designs 16mm-1B high-speed rotary prism camera for use at Hurricane Mesa Test Track in Utah (1000 pictures per second).

Company designs 35mm-4B high speed rotary prism camera for atomic tests in the South Pacific. This camera remains today the world’s fastest 35mm rotary prism camera (3200 pictures per second).

Company designs 35mm-4B high speed rotary prism camera for atomic tests in the South Pacific. This camera remains today the world’s fastest 35mm rotary prism camera (3200 pictures per second).

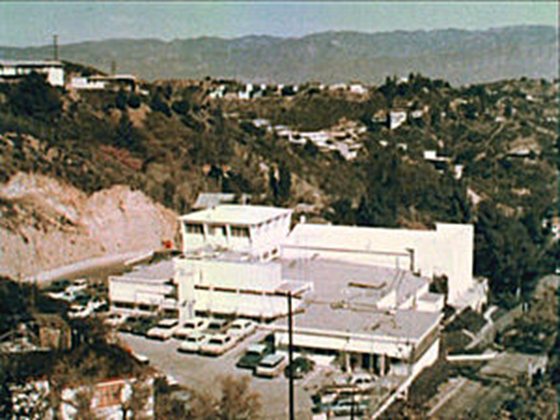

Company moves to new 40,000 square foot facility on Mariposa Street in Burbank.

Company moves to new 40,000 square foot facility on Mariposa Street in Burbank.

Photo-Sonics wins Navy contract to provide technical support for San Clemente Island operations. Forty company employees support photographic, radar, communication and underwater activities.

Photo-Sonics wins Navy contract to provide technical support for San Clemente Island operations. Forty company employees support photographic, radar, communication and underwater activities.

Company develops 16mm-1F high-speed rotary prism camera to evaluate the separation of rocket stages (1000 pictures per second).

Company develops 16mm-1F high-speed rotary prism camera to evaluate the separation of rocket stages (1000 pictures per second).

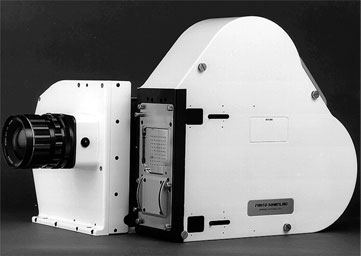

Company designs 70mm-10B high-speed rotary prism camera for atomic tests in the South Pacific. This camera remains today the world’s fastest 70mm rotary prism camera (360 pictures per second).

Company designs 70mm-10B high-speed rotary prism camera for atomic tests in the South Pacific. This camera remains today the world’s fastest 70mm rotary prism camera (360 pictures per second).

Company designs the 70mm-CFA streak camera for evaluating test items on high speed sleds (150 feet per second). Camera sees extensive use at Holloman AFB and China Lake NWC.

Company designs the 70mm-CFA streak camera for evaluating test items on high speed sleds (150 feet per second). Camera sees extensive use at Holloman AFB and China Lake NWC.

Company delivers the first Cine-Sextant Optical Tracking Mount to the U.S. Navy at Point Mugu. The Cine-Sextant was designed to replace modified gun turrets that were being used at that time to acquire optical data.

Company delivers the first Cine-Sextant Optical Tracking Mount to the U.S. Navy at Point Mugu. The Cine-Sextant was designed to replace modified gun turrets that were being used at that time to acquire optical data.

Company develops 16mm-1E miniature high-speed rotary prism camera to evaluate rocket stage separation (600 pictures per second).

Company develops 16mm-1E miniature high-speed rotary prism camera to evaluate rocket stage separation (600 pictures per second).

Company employees working under contract for the Navy and using US Navy CCURV (Cable Controlled Underwater Recovery Vehicle) recovered a hydrogen bomb "lost" off Palomares, Spain.

For further information, please click on the following link:

http://en.wikipedia.org/wiki/Palomares_hydrogen_bombs_incident

Company employees working under contract for the Navy and using US Navy CCURV (Cable Controlled Underwater Recovery Vehicle) recovered a hydrogen bomb "lost" off Palomares, Spain.

For further information, please click on the following link:

http://en.wikipedia.org/wiki/Palomares_hydrogen_bombs_incident

Company develops its first Mil-Std camera, the KB-19A, used extensively in Vietnam to document the effectiveness of ordnance dropped from fighter aircraft.

Company develops its first Mil-Std camera, the KB-19A, used extensively in Vietnam to document the effectiveness of ordnance dropped from fighter aircraft.

Company wins competitive “shoot-out” at Nellis AFB and a contract for its KB-25A Gunsight cameras used on F-4 aircraft. Company eventually designs and produces 5000 Gunsight and HUD cameras for every fighter aircraft in the U.S. inventory with the exception of the F-15.

Company wins competitive “shoot-out” at Nellis AFB and a contract for its KB-25A Gunsight cameras used on F-4 aircraft. Company eventually designs and produces 5000 Gunsight and HUD cameras for every fighter aircraft in the U.S. inventory with the exception of the F-15.

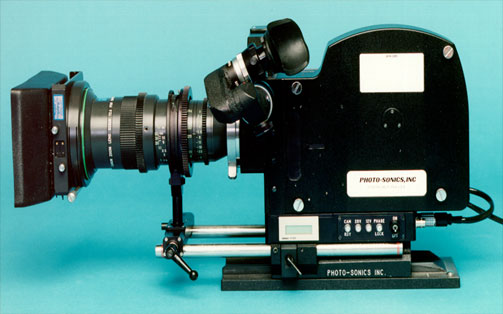

Company designs 16mm-1PDL ActionMaster-500 camera documentary camera (500 pictures per second).

Company designs 16mm-1PDL ActionMaster-500 camera documentary camera (500 pictures per second).

Company designs and delivers Mirror Mount Tracking Systems for the test and evaluation of the Sprint Missile System (2200 degrees per second per second acceleration)

Company designs and delivers Mirror Mount Tracking Systems for the test and evaluation of the Sprint Missile System (2200 degrees per second per second acceleration)

Company forms International Instrumentation Marketing Corporation (IIMC) located in Thames, UK to distribute and service Photo-Sonics products in Europe (later renamed Photo-Sonics International Limited).

Company forms International Instrumentation Marketing Corporation (IIMC) located in Thames, UK to distribute and service Photo-Sonics products in Europe (later renamed Photo-Sonics International Limited).

Car Crash Testing at Ford Motor Company Eight 16mm 1B Cameras

Car Crash Testing at Ford Motor Company Eight 16mm 1B Cameras

Company receives contract to develop Airborne Ground Equipment for the KB-25 and KB-26 series of Gunsight cameras.

Company receives contract to develop Airborne Ground Equipment for the KB-25 and KB-26 series of Gunsight cameras.

Company designs 70mm 14S hand-held camera with reflex viewing. The camera is capable of shooting up to 20 pictures per second.

Company designs 70mm 14S hand-held camera with reflex viewing. The camera is capable of shooting up to 20 pictures per second.

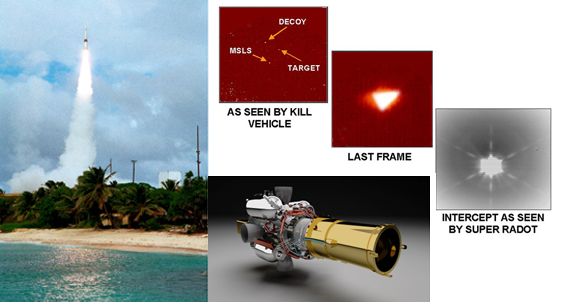

Company is awarded a contract to design 35mm-4CL phase lock camera for the test of the Patriot 3 missile at the White Sands Missile Range. The 4CL is capable of 2000 frames per second while phased locked to within 20 degrees.

Company is awarded a contract to design 35mm-4CL phase lock camera for the test of the Patriot 3 missile at the White Sands Missile Range. The 4CL is capable of 2000 frames per second while phased locked to within 20 degrees.

In 1998, Photo-Sonics undertook the development of tracking mount control software that completely integrates all aspects of an optical tracking system including the tracking pedestal control, sensors, optics, remote control, auto tracker, radar, star calibration, target simulation, data recording, built-in test (BIT) and diagnostics. Multiple systems have been delivered to:

Vandenberg AFB (5)

Redstone Arsenal (2)

Italian Ministry of Defense (4)

Government of Israel (3)

Israeli Military Industries (1)

Korea (2)

In 1998, Photo-Sonics undertook the development of tracking mount control software that completely integrates all aspects of an optical tracking system including the tracking pedestal control, sensors, optics, remote control, auto tracker, radar, star calibration, target simulation, data recording, built-in test (BIT) and diagnostics. Multiple systems have been delivered to:

Vandenberg AFB (5)

Redstone Arsenal (2)

Italian Ministry of Defense (4)

Government of Israel (3)

Israeli Military Industries (1)

Korea (2)

Company to deliver Computer Automated Tracking System to the Italian Ministry of Defense for installation on the island of Sardinia.

Company to deliver Computer Automated Tracking System to the Italian Ministry of Defense for installation on the island of Sardinia.

Development begins on the Nano-Sextant Compact Tracking Mount. The Nano-Sextant is a two-man lift tracking mount that wieghs in at only 140 for the main pedestal (unloaded). The specifications can be viewed on the Nano-Sextant Tracking Mount data sheet and web page.

Development begins on the Nano-Sextant Compact Tracking Mount. The Nano-Sextant is a two-man lift tracking mount that wieghs in at only 140 for the main pedestal (unloaded). The specifications can be viewed on the Nano-Sextant Tracking Mount data sheet and web page.

Development commences on the Mobile Multi-Spectral TSPI System (MMTS). The MMTS is a medium-duty tracking mount that is easily "trailered" from test location-to-location as needed. The system is optimized to automatically track and capture Time-Space-position-Information (TSPI) of the world’s fastest hypervelocity missiles and projectiles. Demonstration videos of the MMTS' capabilities are available for viewing on our web Video Gallery. You can also view the data sheet and MMTS web page.

Development commences on the Mobile Multi-Spectral TSPI System (MMTS). The MMTS is a medium-duty tracking mount that is easily "trailered" from test location-to-location as needed. The system is optimized to automatically track and capture Time-Space-position-Information (TSPI) of the world’s fastest hypervelocity missiles and projectiles. Demonstration videos of the MMTS' capabilities are available for viewing on our web Video Gallery. You can also view the data sheet and MMTS web page.

Photo-Sonics is awarded a contract to install an optical tracking system on the Navy’s new Self Defense Test Ship (SDTS). The U.S.S Paul F. Foster, plays a significant role in the Navy’s future. It is part of a program that has proven its efficiency by providing the most realistic combat scenarios for test events, while leaving ships and their Sailors available to the fleet to perform their normal duties. Please view this press release for more details. A demonstration video of the stablized tracking mount on the ship can be viewed on our Video Gallery. (Scroll about 2/3rds of the way down until you find the video title Tracking Stabilization - Self Defense Test Ship.)

Photo-Sonics is awarded a contract to install an optical tracking system on the Navy’s new Self Defense Test Ship (SDTS). The U.S.S Paul F. Foster, plays a significant role in the Navy’s future. It is part of a program that has proven its efficiency by providing the most realistic combat scenarios for test events, while leaving ships and their Sailors available to the fleet to perform their normal duties. Please view this press release for more details. A demonstration video of the stablized tracking mount on the ship can be viewed on our Video Gallery. (Scroll about 2/3rds of the way down until you find the video title Tracking Stabilization - Self Defense Test Ship.)

The F-16 Cockpit Camera (CCAM) is created. This camera is the latest in a long line of F-16 cameras and has excellent environmental characteristics incorporating superb image quality with high reliability ( >22,000 MTBF). The camera is lightweight and designed around single-unit construction. It is easily installed and aligned in the aircraft in less than one hour. For further information on this camera, please view the data sheet and the camera's web page.

The F-16 Cockpit Camera (CCAM) is created. This camera is the latest in a long line of F-16 cameras and has excellent environmental characteristics incorporating superb image quality with high reliability ( >22,000 MTBF). The camera is lightweight and designed around single-unit construction. It is easily installed and aligned in the aircraft in less than one hour. For further information on this camera, please view the data sheet and the camera's web page.

Photo-Sonics, Inc. celebrates 90 years in business!

Photo-Sonics, Inc. celebrates 90 years in business!

Photo-Sonics, Inc. moves to a new facility in Chatsworth, CA. The new building has roughly the same floor space area incorporated into a much newer facility. Take a look at the new location on our homepage.

Photo-Sonics, Inc. moves to a new facility in Chatsworth, CA. The new building has roughly the same floor space area incorporated into a much newer facility. Take a look at the new location on our homepage.